The question “What is the difference between an analog and digital tachometer?” is one of the most frequently searched queries when considering a tachometer for its applications. Tachometers, analog or digital, are essential for measuring the rotational speed (RPM) of machinery, engines, and other mechanical devices. However, the way they display and measure speed differs significantly. This recap will explain the key differences between analog and digital tachometers, helping you decide which type suits your needs.

- Display Mechanism: Needle vs. Digital Screen

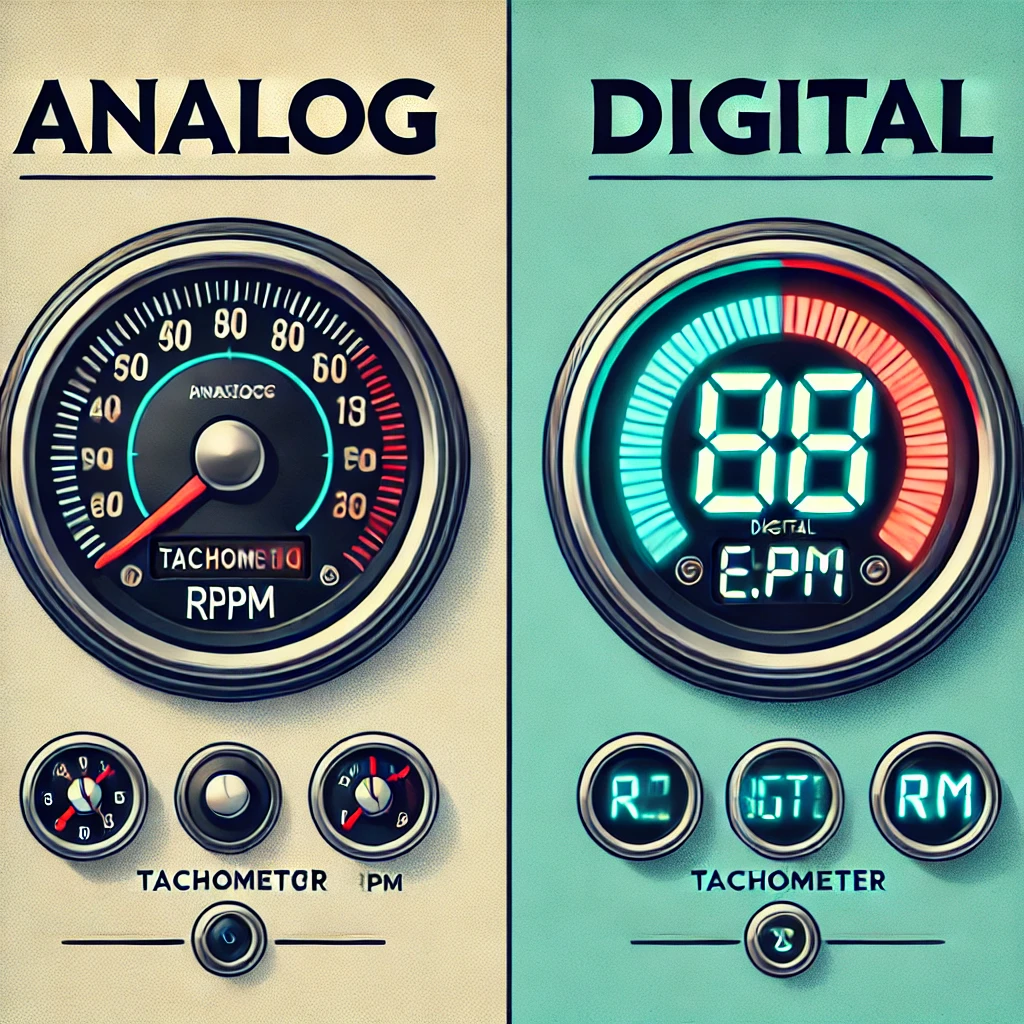

The most apparent difference between analog and digital tachometers is their display mechanism.

- Analog Tachometer: Analog tachometers use a physical needle and a dial to show the rotational speed. The needle points to a specific value on a circular dial, and users interpret the RPM based on the needle’s position. The scale on the dial may be marked in either RPM or another relevant unit of measure, depending on the type of machine or system being monitored. Analog tachometers are straightforward but require users to read and estimate the exact value based on the needle’s position, which can sometimes be imprecise.

- Digital Tachometer: As the name implies, digital tachometers provide a numerical readout of the RPM on a digital display. These tachometers are equipped with electronic sensors that measure the speed and instantly convert it into a digital format on a screen. This numerical output offers precise, easy-to-read results, eliminating any guesswork associated with interpreting a needle’s position on an analog dial. Digital tachometers usually display RPM to the exact number, often with additional decimal places for even greater precision.

Why This Matters: A tachometer’s digital display is a major advantage for most users, as it provides clear, easy-to-understand readings with no ambiguity. It’s beneficial when exact measurements are crucial, such as in high-precision industrial work or automotive diagnostics.

- Accuracy and Precision

When it comes to accuracy, digital tachometers typically outperform analog models. Here’s why:

- Analog Tachometer Accuracy: Although analog tachometers can be accurate, their readings are generally less precise. Since the reading is based on a moving needle, there is a margin for error due to parallax (the apparent shift in the position of the needle depending on the angle from which it’s viewed). Additionally, mechanical wear and tear can affect the accuracy of an analog tachometer over time.

- Digital Tachometer Accuracy: Digital tachometers are more accurate because the RPM is calculated electronically, eliminating mechanical components that might degrade. They often use optical or magnetic sensors, which are more reliable and consistent. As a result, digital tachometers are usually more accurate, especially when precise measurements are required for high-performance engines or sensitive machinery.

Why This Matters: Digital tachometers provide a clear advantage in applications where accuracy is vital—such as calibrating machinery, diagnosing engine performance, or monitoring manufacturing processes. Their precision reduces the risk of errors, ensuring machinery operates within the correct RPM range.

- Ease of Use and Readability

Digital tachometers are generally more user-friendly and easier to read compared to their analog counterparts.

- Analog Tachometer: Reading an analog tachometer requires estimating RPM based on the needle’s position, which can be challenging for inexperienced users or when the needle moves quickly. Additionally, it can be challenging to read in low light, especially if the dial markings are small or unclear.

- Digital Tachometer: Digital tachometers are designed to be easy to read, with large, precise numbers that display the RPM directly. Most models also feature backlit screens, making them more visible in low-light environments. Furthermore, depending on the model, digital tachometers can display additional information such as maximum RPM, average RPM, or error messages.

Why This Matters: The ease of reading a digital tachometer makes it much more convenient, especially when you need to monitor RPMs quickly or while working in dimly lit conditions. It also reduces the chances of misinterpreting the readings, which can happen with analog models.

for more info

- Additional Features and Functionality

Digital tachometers often come with more advanced features compared to analog models.

- Analog Tachometer: Analog tachometers are typically simple devices with just a needle and a scale. Some may have additional features, like a mechanical memory with maximum RPM, but these features are limited compared to digital versions.

- Digital Tachometer: Digital tachometers offer a variety of extra features, such as:

- Data logging: Some digital tachometers can store measurement data for later analysis.

- Memory recall: Many models allow you to store and recall maximum or average RPM readings.

- Multiple unit conversions: Digital tachometers can easily switch between different units of measurement, like RPM, Hz, or other rotational speed units.

- Battery indicators and alerts: Some digital tachometers provide battery life status and will alert you when maintenance is required.

Why This Matters: Digital tachometers’ advanced features make them more versatile and useful for different applications, especially in industries where data logging, memory recall, or unit conversions are necessary. These added functionalities enhance the overall user experience and make digital tachometers more suitable for modern tasks.

- Durability and Maintenance

Both analog and digital tachometers have their durability characteristics, but digital models are generally easier to maintain.

- Analog Tachometer: Analog tachometers are often more robust in physical durability. Since they have fewer electronic components, they can withstand harsh environments, such as extreme temperatures or rough handling. However, mechanical parts may wear out over time, causing the device to lose accuracy.

- Digital Tachometer: Digital tachometers are generally more sensitive to environmental factors like extreme temperatures, moisture, or shock. However, they often have protective casings or are designed to be water-resistant, making them durable enough for most industrial applications. Maintaining digital tachometers involves simple tasks like replacing batteries or recalibrating the device.

Why This Matters: The tachometer’s durability is essential for heavy-duty or outdoor applications. While analog tachometers may handle extreme conditions better, digital tachometers offer more long-term reliability, especially in controlled environments.

Conclusion: Which Should You Choose?

Both analog and digital tachometers have their place in various industries and applications. Analog tachometers, with their simple mechanical design, are often used when durability and reliability are more important than precision. Digital tachometers, on the other hand, excel in accuracy, ease of use, and advanced features, making them the preferred choice for most modern applications.

A digital tachometer is likely the better choice if you require high precision, clear readability, and advanced features. However, an analog tachometer may be more suitable for straightforward, rugged uses.